Breaking the Rules of Chemistry®

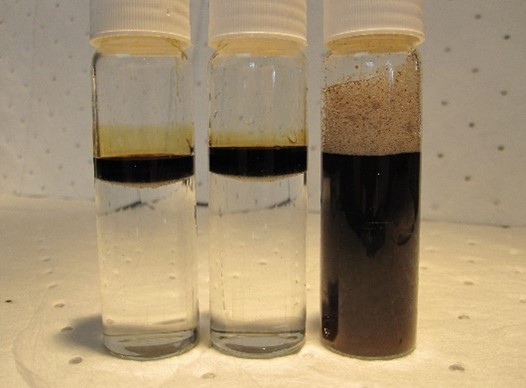

Contaminant sorption and NAPL formation are the most significant limiting factor that reduces the availability of petroleum hydrocarbons and chlorinated solvents for physical, biological and chemical remediation within soil, fractured bedrock and groundwater. This coupled with the high surface tension of groundwater (73 Dynes) results in pore space pathway interferences caused by 'interfacial tension' existing between the groundwater, vapour, sorbed and NAPL (LNAPL, DNAPL) phases. These collectively work to limit the ‘Access' to and 'Availability’ of contaminants for all forms of remediation, explaining why many remediation projects are slow, costly, and/or fail!

Fortunately, Ivey-sol® has the unique ability to selectively desorb sorbed and NAPL phases into groundwater, and overcoming interfacial tension, whereby breaking many conventional hydro-geo-chemical rules to significantly improve contaminant availability for in-situ and ex-situ remediation. This capacity produces substantial and measurable benefits when treating vapour intrusion, soil, bedrock, and groundwater contamination.

- Ivey-sol® makes insoluble contaminants miscible.

- Ivey-sol® reduces water surface tension, improving K in finer grain geology.

- Ivey-sol® overcomes interfacial tension (resolving limitations of Henry and Raoult's laws) .

- Ivey-sol® is the only selective sub CMC surfactant technology to treat petroleum hydrocarbons, chlorinated solvents, organometalics, and emerging contaminants, like PFAS.

- By breaking the rules of hydro-geo-chemistry, Ivey-sol® improves contaminant accessibility for all forms of physical (MPE, DPVE, P&T, Thermal), biological (aerobic and/or anaerobic), and chemical (REDOX) methods.

IVEY-SOL FOR IN-SITU REMEDIATION

Since the formation of USEPA (December 1970) and the first Earth Day (April 1970), site assessment remediation has been inundated with many challenges. With many practitioners learning as they go, managing the broadening range of physical, biological, and chemical remediation methods available to them, in-situ and ex-situ remediation has remained a challenging endeavour. Consequently, many sites have been subjected to a plethora of iterative multi-year remediation applications, contaminant-rebound (mass flux), with only partial remediation associated with diminishing rates of impact reduction, and becoming common costly application eulogies.

This is often due to the over-simplification of conceptual site models and associated remediation plans, with reliance on just one (1) remediation technology, or overly complicated treatment plans that pitch ‘elaborate multi-variable management’ and/or use of non-complimentary remediation method combinations (eg. ISCO to treat NAPL). Although these approaches appear very 'novel and clever’, they still fail to address fundamental contaminant hydro-geo-chemical behaviour, phase partitioning, a.k.a. Sorption (Adsorption and Absorption) and NAPL (LNAPL & DNAPL) formation, water clusters, and interfacial tension, which greatly limit target contaminant availability for most remediation technologies, with very few exceptions!

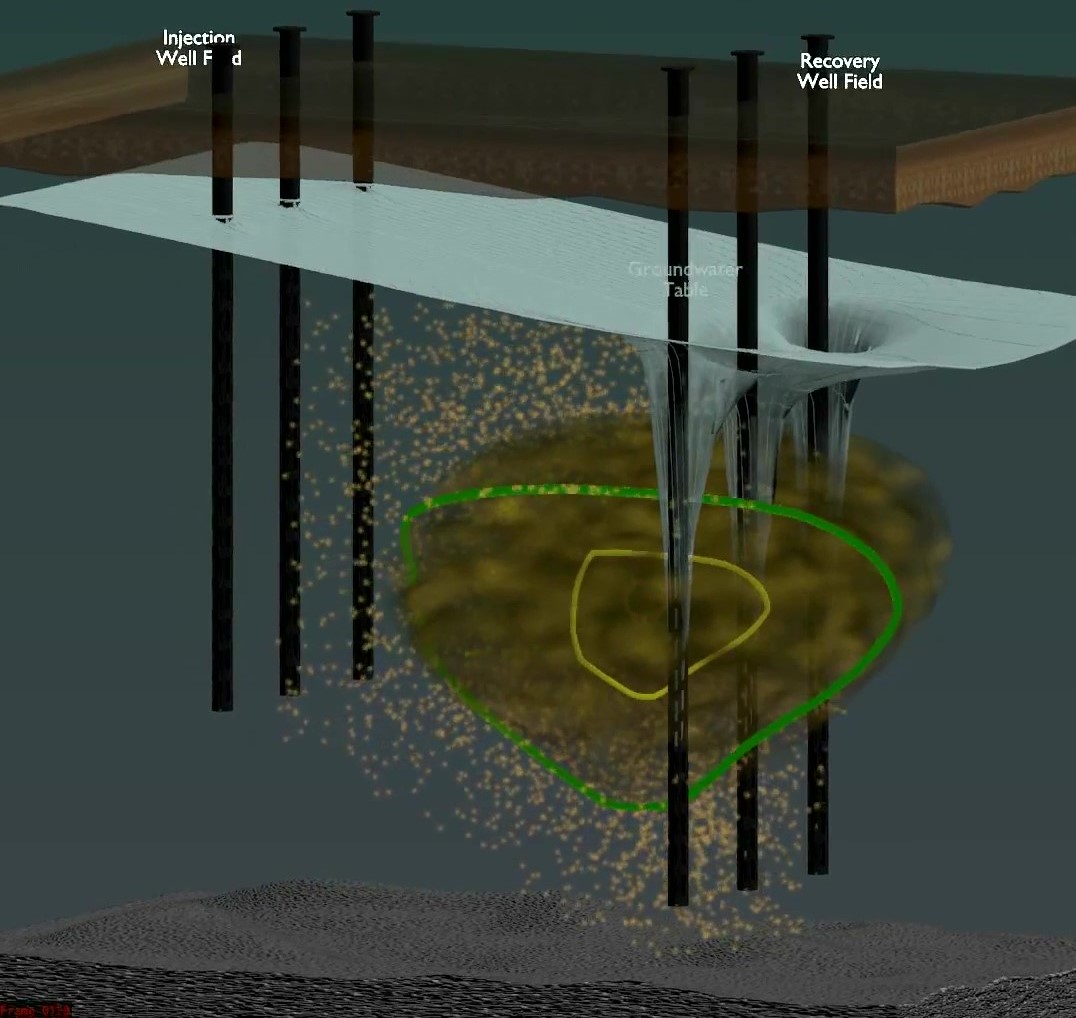

Ivey-sol® Surfactant Remediation Technology, provides an evidence-based solution to overcome contaminant phase-partitioning, interfacial tension, and reducing size of water clusters to increase K in finer texture geology, to enhance physical, biological, and chemical remediation to acheive more consistent project clean-up goals, with measurable time and cost savings.

KNOCK KNOCK, VAPOUR INTRUSION

Vapour intrusion, of volatile and semi-volatile organic contaminants (VOC), is often driving the in-situ remediation of many soil and groundwater impacted sites globally. Where VOC (i.e. petroleum hydrocarbons, chlorinated solvents, moulds, etc.) contaminants reside, in hard to access locations such as under buildings, roadways, rail lines, and similar areas, vapour extraction systems (VES) and/or engineered controls are often used in an effort to mitigate direct-contact pathway risks. Ivey-sol® has the unique ability to interact with VOC’s at a molecular level, making them more miscible in the aqueous phase, and less volatile, allowing for their enhanced mass removal at multi-phase extraction (MPE), and/or similar systems. Enhancement of VOC mass recovery, increased by several hundred to several thousand percent being observed at sites, with Ivey-sol® achieving more VOC mass removal in weeks compared to the MPE mass removal in years.

EX-SITU REMEDIATION

Ivey-sol® is also very effective for enhancing ex-situ physical, biological and chemical remediation of petroleum, chlorinated solvents, and organometallic impacted soils. As Ivey-sol® overcomes contaminant sorption, it makes the sorbed contaminant more ‘Available’ for enhanced remediation by techniques that include:

- Ex-situ Soil Washing

- Ex-situ Bioremediation

- Ex-situ Chemical REDOX

- Thermal Desorption

IVEY developed and trademarked the following processes:

■ SER - Surfactant Enhanced RemediationSM

In-situ and ex-situ application processes to liberate sorbed and/or NAPL making them more miscible (soluble) and more ‘Physically-Available’ for mass removal via ex-situ soil washing and thermal desorption;

■ SEB - Surfactant Enhanced BioremediationSM

In-situ and ex-situ application processes to liberate sorbed contaminants making them more ‘Biologically Available’ for microbial (bacteria and fungi) and associated enzymatic degradation. SEB enhances all bioremediation methods including: bio-stimulation, bio-augmentation, and newer enhanced biological techniques for aerobic, anaerobic and facultative microbial mineralization.

■ SEC - Surfactant Enhanced Chemicalization®

In-situ and ex-situ application processes to liberate sorbed contaminants making them more ‘Chemically-Available’ for chemical REDOX (i.e. Reduction, Oxidation and/or combined Reduction-Oxidation) by chemical agents. SEC improves the availability of the contaminants to the chemical REDOX, facilitating improved contact and reaction kinetics, to enhance the chemical reagent degradation of target contaminants. This process may also be modified for application with chemical REDOX reagents for ex-situ soil applications for a broad range of COC and/or as a preliminary step to ex-situ SER, SEB, or SEC treatment remediation.

Ready to Get Started?

Get in touch with IVEY to develop site-specific in-situ and ex-situ application strategies, bench scale testing, and/or technical application support.

Client Case Studies

Read and learn more about successful cost-effective site applications and collaborative projects IVEY has worked on with their local and international clients.